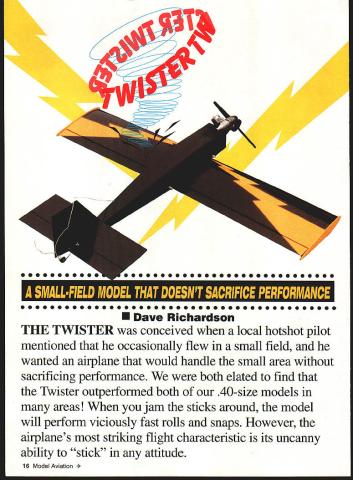

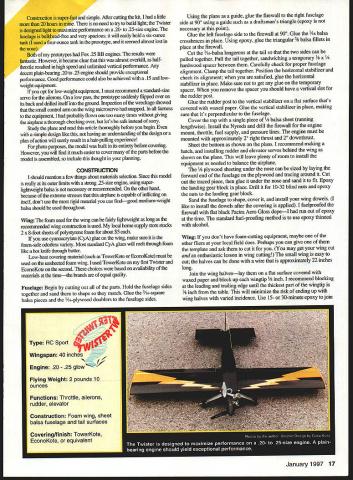

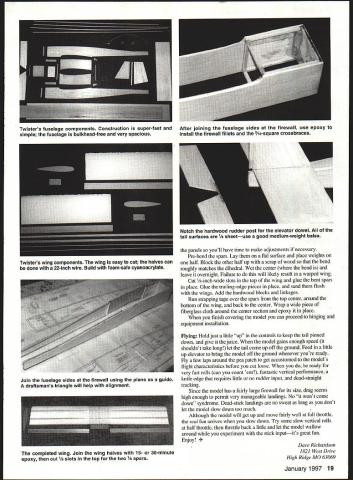

S 000000000000000500... 0000000 00000 0000 U Dave Richardson THE TWISTER conceived local hotshot pilot mentioned occasionally flew small field wanted airplane would handle small area sacrificing performance both elated find Twister outperformed both 40-size models areas jam sticks around model will perform viciously fast rolls snaps However airplanes striking flight characteristic its uncanny ability stick attitude 16 Model Aviation S S @00000000000000 S Sees CtnLii super-fast simple After cutting kit little flKE*I1 2Ohoi*innine no need ty build light Twister i@dligIttO iiaximize pesfomiance 20- 25-size engine 6zamishiead-flee veiy spacious will easily hold six-ounce tank used four-ounce tank prototype seemed almost lost dienose Both prototypes Fox 25 BB engines results ntastiHoweveril became dear almost overkiWashaif decent plain-bearing 20 25 engine should provide exceptional performance Good performance could also achieved 15 lowweight equipment opt low-weight equipment must recommend standani-size servo ailerons low pass prototype suddenly flipped over its back drilled itself ground Inspection wreckage showed small control ann wing microservo snapped lii fairness equipment probably flown too times giving airplane thorough checking over lets safe instead sony Study plans read article thoroughly before begin simple design like having understanding design plan action will surely result hair-pulling experience photo purposes model built its entirety before covering However will find much easier cover pails before model assembled include thought planning CONSTRUCilON should mention few things about materials selection Since model really its outer limits strong 25-size engine using superlightweight balsa necessaiy recommended other hand because extreme stresses airplane capable inflicting itself dont use rigid material can findgood medium-weight balsa should used throughout Wing foam used wing can fairly lightweight long recommended wing construction used local home supply store stocks 2 x 8-foot sheets polystyrene foam about $5 use cyanoactylate CyA glue wing make sure foam-safe odorless variety Most standard CyA glues will melt through foam like hot knife through butter Low-heat covering material such TowerKote EconoKote must used unsheeted foam wing used TowerKote first Twister EconoKote second choices based availability materials time4he brands equal quality Fuselage Begin cutting out parts Hold fuselage sides together sand shape match Glue 3/16-square balsa pieces 1A6-plywood doublers fuselage sides Using plans guide glue firewall right fuselage side 900 using guide such draftsmans triangle epoxy necessary point Glue left fuselage side firewall 900 Glue 3A6 balsa crossbraces place Using epoxy glue triangular 3A balsa fillets place firewall Cut lsa longerons tail two sides can pulled together Pull tail together sandwiching temporary 1A x hardwood spacer between Carefully check proper fuselage alignment Clamp tail together Position horizontal stabilizer check its alignment satisfied glue horizontal stabilizer place Make sure get glue temporary spacer remove spacer should have vertical slot rudder post Glue rudder post vertical stabilizer flat surface thats covered waxed paper Glue vertical stabilizer place making sure its perpendicular fuselage Cover top single piece 1A balsa sheet running lengthwise Install Nyrods drill firewall engine mount throttle fuel supply pressure lines engine must mounted approximately 20 right thrust 20 downthrust Sheet bottom shown plans recommend making hatch installing rudder elevator servos behind wing shown plans will leave plenty room install equipment needed balance airplane 1A plywood sheeting under nose can sized laying forward end fuselage plywood tracing around Cut out traced piece glue under nose sand fit Epoxy landing gear block place Drill 10-32 blind nuts epoxy nuts landing gear block Sand fuselage shape cover install wing dowels like install dowels after covering applied fuelproofed firewall flat black Pactra Aero Gloss dopeI run out epoxy time standard fuel-proofing method use epoxy thinned alcohol Wing dont have foam-cutting equipment maybe other fliers local field does Perhaps can give template ask cut may get wing cut enthusiastic lesson wing cutting small wing easy cut halves can done wire approximately 22 inches long Join wing halveslay flat surface covered waxed paper block up wingtip recommend blocking leading trailing edge until thickest part wingtip 1A inch table will minimize risk ending up wing halves varied incidence Use 15- 30-minute epoxy join January1997 17 N Notch hardwood rudder post elevator dowel tail surfaces 1/8 sheetuse good medium-weight balsa panels youll have time make adjustments necessary Pre-bend spars Lay flat surface place weights half Block other half up scrap wood bend roughly matches dihedral Wet center bend leave overnight Failure will likely result warped wing Cut 1/s-inch-wide slots top wing glue bent spars place Glue trailing-edge pieces place sand flush wings Add hardwood blocks linkages Run strapping tape over spars top center around bottom wing back center Wrap wide piece fiberglass cloth around center section epoxy place finish covering model can proceed hinging equipment installation Flying Hold just little up controls keep tail pinned down give juice model gains enough speed shouldnt take long let tail come up off ground Feed little up elevator bring model off ground whenever youre ready Fly few laps around pea patch get accustomed models flight characteristics before cut loose ready very fast rolls can count em fantastic vertical performance knife edge requires little no rudder input dead-straight tracking Since model has fairly large firewall its size drag seems high enough permit very manageable landings No wont come down syndrome Dead-stick landings no sweat long dont let model slow down too much Although model will get up move fairly well full throttle real fun arrives slow down Iry some slow vertical rolls half throttle throttle back little let model wallow around experiment stick inputits great fun Enjoy Richardson 1821 West Drive High Ridge MO 63069 January 1997 19 Twisters fuselage components Construction super-fast simple fuselage bulkhead-free very spacious After joining fuselage sides firewall use epoxy install firewall fillets 3/1e-square crossbraces Twisters wing components wing easy cut halves can done 22-inch wire Build foam-safe cyanoacrylate Join fuselage sides firewall using plans guide draftsmans triangle will help alignment completed wing Join wing halves 15- 30-minute epoxy cut /e slots top two /a spars