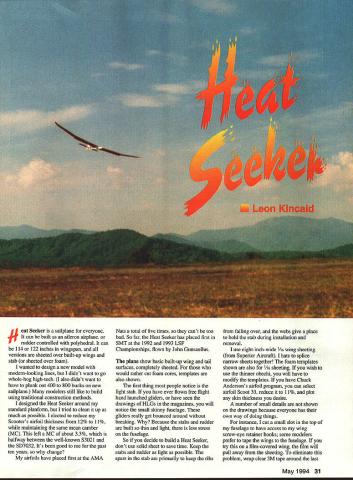

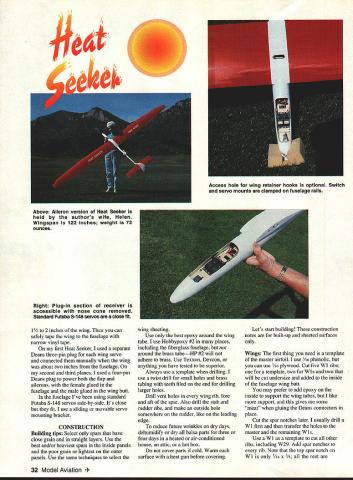

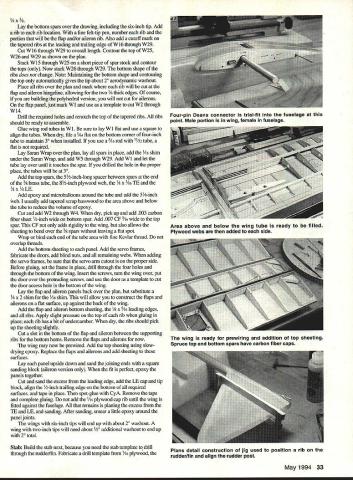

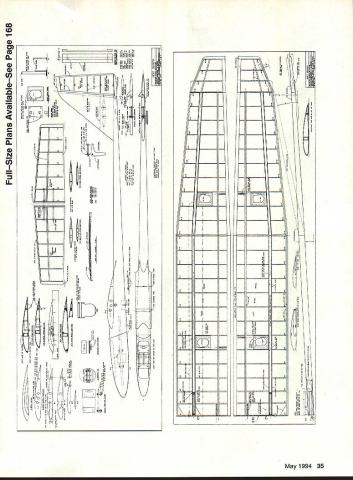

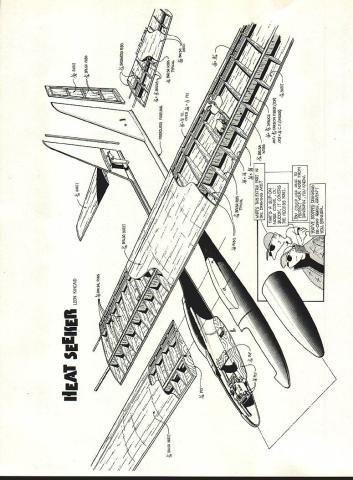

seat Seeker sailplane everyone can built aileron airplane rudder controlled polyhedral can 114 122 inches wingspan versions sheeted over built-up wings stab sheeted over foam wanted design new model modem-looking lines didnt want go whole-hog high-tech also didnt want have plunk out 400 800 bucks new sailplane modelers still like build using traditional construction methods designed Heat Seeker around standard planform tried clean up much possible elected reduce Scooters airfoil thickness 12% 11% maintaining same mean camber MC left MC about 33% halfway between well-known S3021 5D7032 Its good past ten years change airfoils have placed first AMA Nats total five times cant too bad So far Heat Seeker has placed first SMT 1992 1993 LSF Championships flown John Gunsaullus plans show basic built-up wing tail surfaces completely sheeted would rather cut foam cores templates also shown first thing people notice light stab have ever flown free flight hand launched gliders have seen drawings HLGs magazines will notice small skinny fuselage gliders really get bounced around breaking Because stabs rudder built thin light less stress fuselage So decide build Heat Seeker dont use solid sheet save time Keep stabs rudder light possible spars stab primarily keep ribs falling over webs give place hold stab during installation removal use eight-inch-wide 1/16 wing sheeting Superior Aircraft hate splice narrow sheets together foam templates shown also 1/16 sheeting wish use thinner obechi will have modify templates have Chuck Andersons airfoil program can select airfoil Scoot 33 reduce 11% plot skin thickness desire number small details shown drawings because everyone has own way doing things instance cut small slot top fuselage have access wing screw-eye retainer hooks some modelers prefer tape wings fuselage try film-covered wing film will pull away sheeting eliminate problem wrap clear 3M tape around last May1994 31 Right Plug-in section receiver accessible nose cone removed Standard FUtaba 5-148 servos close fit 1 /2 2 inches wing can safely tape wing fuselage narrow vinyl tape first Heat Seeker used separate Deans three-pin plug wing servo connected manually wing about two inches fuselage second third planes used four-pin Deans plug power both flap ailerons female glued fuselage male glued wing butt fuselage Ive using standard Futaba S-148 servos side-by-side Its close fit use sliding movable servo mounting bracket CONSTRUCTION Building tips Select spars have close gram stralght layers Use best andlor heaviest spars inside panels poor grain lightest outer panels Use same techniques select wing sheeting Use best epoxy around wing tube use Hobbypoxy #2 places including fiberglass fuselage around brass tubeHP #2 will adhere brass Use Texxon Devcon anything have tested superior Always use template drilling use twist drill small holes brass tubing teeth filed end drilling larger holes Drill vent holes wing rib fore aft spar Also drill stab rudder ribs make outside hole somewhere rudder like leading edge reduce future wrinides dry days dehumidify dry balsa parts three four days heated air-conditioned house attic hot box cover parts cold Warm surface heat gun before covering Lets start building construction notes built-up sheeted surfaces Wings first thing need template master airfoil use A6 phenolic can use /is plywood Cut five Wi ribs template two Wis two will cut undersize added inside fuselage wing butt may prefer add epoxy inside support wing tubes like support gives some meat gluing Deans connectors place Cut spar notches later usually drill Wi first transfer holes master remaining Wis Use Wi template cut other ribs including W29 Add spar notches rib Note top spar notch Wi /is x 3/s rest 32 Model Aviation e Aileron version Heat Seeker held authors wife Helen Wingspan 122 inches weight 72 ounces Access hole wing retainer hooks optional Switch servo mounts clamped fuselage rails /8 x 3/8 Lay bottom spars over drawing including six-inch tip Add rib rib location fine felt-tip pen number rib portion will flap and/or aileron rib Also add cutoff mark tapered ribs leading trailing edge W16 through W29 Cut W16 through W29 overall length Contour top W25 W26 W29 shown plan Stack W15 through W25 short piece spar stock contour tops Now stack W26 through W29 bottom shape ribs does change Note Maintaining bottom shape contouring top automatically gives tip about 20 aerodynamic washout Place tibs over plan mark rib will cut flap aileron hingeline allowing two thick edges course building polyhedral version will cut ailerons flap panel just mark Wi use template cut W2 through W14 Drill required holes renotch top tapered ribs ribs should ready assemble Glue wing rod tubes Wi sure lay Wl flat use square align tubes dry file /6a flat bottom comer four-inch tube maintain 30 installed use 46 rod 2 tube flat required Lay Saran Wrap over plan lay spars place add A6 shim under Saran Wrap add W5 through W29 Add Wl let tube lay over until touches spar drilled hole proper place tubes will 3O Add top spars 5-inch-long spacer between spars end 3/8 brass tube 8-inch plywood web x 5/is TB /8 X ALE Add epoxy microballoons around tube add 5-inch web usually add tapered scrap basswood area above below tube reduce volume epoxy Cut add W2 through W4 dry pick up add 003 carbon fiber sheet -inch wide bottom spar Add 007 CF 3/is wide top spar CF adds rigidity wing also allows sheeting bend over 3/8 spars leaving flat spot Wrap bind end tube area fine Kevlar thread overlap threads Add bottom sheeting panel Add servo frames fabricate doors add blind nuts remaining webs adding servo frames sure servo arm cutout proper side Before gluing set frame place drill through four holes through bottom wing Insert screws tum wing over put door over protruding screws use door template cut door access hole bottom wing Lay flap aileron panels back over plan substitute 1/8 x 2 shim /16 shim will allow construct flaps ailerons flat surface up against back wing Add flap aileron bottom sheeting Ax 5A6 leading edges ribs Apply slight pressure top rib gluing place rib has bit undercamber dry ribs should pick up sheeting slightly Cut slot bottom flap aileron between supporting ribs bottom horns Remove flaps ailerons now wing may now prewired Add top sheeting using slowdrying epoxy Replace flaps ailerons add sheeting surfaces Lay panel upside down sand joining ends square sanding block aileron version fit perfect epoxy panels together Cut sand excess leading edge add LB cap tip block align -inch trailing edge bottom required surfaces tape place spot-glue CyA Remove tape complete gluing add 1/Is plywood cap rib until wing fitted against fuselage remains planing excess TB LE sanding After sanding smear little epoxy around panel joints wings six-inch tips will end up about 20 washout wing two-inch tips will need about tional washout end up 20 total Stab Build stab next because need stab template drill through rudder/fin Fabricate drill template /16 plywood May1994 33 Four-pin Deans connector trial-fit fuselage point Male portion wing female fuselage Area above below wing tube ready filled Plywood webs added side wing ready prewiring addition top sheeting Spruce top bottom spars have carbon fiber caps Plans detail construction jig used position rib rudderlfin align rudder post same length width Si Leave template rectangular Drill two s stab tubes 1 inches apart 17/is LE Use template cut drill four 116 basswood ribs Si S2 ten 116 balsa ribs Number ribs 51 through S7 Contour Si S7 shown plan two s 12 inches long add ribs side time space over plan Align Si S7 end mark LE TB excess will cut S2 through S6 Stack ribs two short tubes contour S2 through S6 can mark ribs stacked notch spars reinstall 12-inch tubes space mark notch over plan Lay spar over plan add rib spars LE use two tubes building jig careful CyA ribs tubing Add bottom sheeting being careful distort frame Install webs tubing wheel collar lay flat surface Shim long strips balsa under LE TB areas making sure stab twisted Add slow-curing epoxy rib spar LB TB sheeted area Add 003 x A6 carbon fiber sheet TB add epoxy top CF Now add top sheeting Since its hard pin through carbon fiber add two strips 1A x ight stock side TB clamp place dry add tip block /16 cap rib LB cap About wheel collar dont use heavy brass steel collar use Perfect aluminum collar has 2-56 thread okay drill tap 4-40 set screw Use set screws Allen wrench heavy collars Rudder fastest part Lay LB drawing add ribs pick up lay over right side sheeting CyA sheeting LB ribs Dont forget vent holes Add glue CF trailing edge left side sheeting Clamp done stab TB Add top bottom blocks carve sand add horn Fuselage sure nice have fuselage almost completed After carved plug added wing plug-in area wing fillets rudder fin sent fuselage Bob Sealy make mold lay-up fuselages Bob does very precise job fuselage weighs about 10 ounces Wash fuselage thoroughly drill wing rod holes other holes required can epoxy cut-down Wls radii inside corners clear large fiberglass radius inside wing butts before drill fuselage drill fuselage first predrilled Wis later case clamp master aiifoil template side wing butt Take time align top airfoil leading edge Drill side move template other side Put tube way through check see square butt Add tube wing rods slide wing place check fit drilling off can elongate holes slightly Type RC sailplane Wingspan1 14 122 inches Number servos Six Flying weight 72 ounces Construction Fiberglass fuselage sheeted surfaces Covering/finish Hobbypoxy fuselage MonoKote surfaces 34 Model Aviation tubes inserted through stab ribs aid alignment First two ribs stab half 1A6 basswood Fuselage side view shows CG settings female four-pin connector flap aileron homemade towhook four-pin plugs make assembly quick easy Steel front wing rod 11/32 x 10 rear k2 x 6 Source text Stab joined two /32 x 5 steel rods Fully sheeted stab panels weighed 28 grams less rods prior covering FullSize Plans AvailableSee Page 168 ___2F K K_________ --C uilALI I. I141II I _____________ ___ ____________ 11 ___ _________________ NO OCR TEXT add Wis inside tube can located proper place can sand butt wing until fits perfectly perfect can add 1/16 cap ribs wing holes cap ribs should same OD wing rods fabricate servo rails inside contour fuselage Use strong T-pins small nails align glue spruce strips dont have five Y16 x use x use three strips order hold its shape will have sand cut ViA away width servo area Use either epoxy CyA laminate glue fuselage time use clamping type servo mount rail allows move servos around replace different servos no problem After everything right want glue small piece scrap plywood top fuselage rail keep servos sliding forward after hard landings Try clamp mounts least youre fining everything up Insert lower part mounts have blind nuts Add long rails top part mounts insert Allen bolt nuts until assembly comes together dont tighten Attach servos screw mounts Slide assembly forward until servos just touch bottom fuselage servo anns clear fuselage sides Raise whole assembly slightly servos will touch fuselage screws tightened Mark inside and/or outside fuselage rather clear epoxy side rails place can epoxy rails removing everything reinstalling rails marks added add Saran Wrap between clamp/mounts rail reassemble everything Use Hobbypoxy #2 best results have larger servos will have move further aft Fabricate stab hom /io phenolic Draw horizontal stab centerline mdder/ fin using top rear fuselage reference line Mark stab bearing drilled Cut trim fit rib just above hom position Before epoxying rib place drill hole near leading edge run thin-wail teflon tubing up leading edge rudder antenna rib should rudder hinge line Epoxy rib place using alignment jig shown plan Cut trim rudder/fin post epoxy place Use stab drill jig drill stab bearing hole through rudder/fin Since its difficult hold fuselage drill hole drill press fabricated ajig drill perpendicular surface Insert piece tubing wire add wing rod eyeball rear make sure parallel can elongate file hole required add 1/BH plywood doubler inside make sure tube stab bearing level square sides Dont glue stab bearing place yet can machine special stab bushing shown must drill 3/iA hole flangetype bushings need no doublers may now epoxied place SA CHS POWER WALKER MACHINE 58 Engine $59500 42 Engine $52500 32 Engine $45000 26 Engine $45000 $1200 Shipping Distributed BLUE MOUNTAIN 503 938-6743 Fax 503 938-6950 1 7 N Fiizaheth PA Box 777 Milton-Freewater OR 97862 HP2008O SPORT STUNT PLANE%/AfG AIEG j U THE CLEAN LINES OF THE HP 200 REPRESENT MANY CLASSIC DESIGN FEATURES THAT SET THIS BIG BIRD U THE REST THE EASE DFCDNSTRUCTIDNAND AMAZING FLIGHT PERFDRMANCE IS ATTRIBUTED TD U lITS DESIGNER HAL PARENT CDMES IN SEMI-KIT FDRM TD SAVE YDU MDNEY PRICE OF SEMI-KIT $99 95ENGINES 90 TO QUADRA 421I I.LIML WING AREA 1080 SO INTINS DETAILED PLANS WEIGHT 14 TO 16 LBSCONSTRUCTION MANUAL U FOAM WING COWSU U CALL FOAM TURTLE DECK U MIcAcc 009WHEEL PANTS EP1EOCRYSTALCLEARCANOPT - ALUMINUM LANDING EARN HEAVY PLYWOOD MAIN U FIREWALL AND U FORM ERS EDRAL BRACEU HORNS AND WING BOLTS U BILL OP MATERIALS FOB ADDITIONAL WOODU REQUIRED 00 COMPLETE 'THE AIRFRAMEU SEND MAIL ORDERS TO WINS MPG 300 E SIMMONS GALOSBUOG IL 6T401U ADD 57 BS SHIPPING AND HANDLING IN USACALL OR WRITE FOR SHIPPING CHANGES ON FOREIGN ORDERSU May1994 37 LIGHTING SYSTEMS THE ORIGINALS. Still Best #RAM 01Programmable Flashing Navigation Lights 9V$2495 #RAM 02Strobe Light Adj Rate 9V$1995 #RAM 03Landing Lights 48V$3995 CRAM 04Mars Rotating Beacon Adj Rate 9V$1995 #RAM 05Marine Navigation Lights nonflashing 9V$1095 #RAM 06Sky Lights 18 Light Set 9V$2495 #RAM 14Big Airplane Navigation Lights 9V$2495 #RAM 16Econo Landing Lights brightest 9V$1995 #RAM 23Real Strobe Light true zenon strobe 3V$2995 0 SEE YOUR DEALER e SEND STAMPED ENVELOPE FOR RAM INFO unavailable locally aend check money order full credIt card info coat item plus $400 $500 foreignfor immediate shIpment Include full address U PS Sorry no COD cRam 229A E Rollins Rd d Lake Beach IL 60073 Satisfaction Guaranteedl SH-710 Pkg 0824 $2 95 EA~ HINE THE HIGH-TECH HINGE DESIGNED FOR THE CYANOACRYLATE AGE Easier install other hinge No gouging picking messy epoxies Simply cut single knife slot hinge slide hinges place apply few drops favorite CA glue youre donel SUPER FAST SUPER EASY SUPER STRONG 74e4t UC9e4 /oCe e4 MFG CO INC.401-7 So Front St.Montezuma IA 50171 23-5154 Engine Test Ran repair update Sachs style Engines t Selection El] 55 72 14 2 316&60z EDEEJED Super Prices U 14 oz 38w Plain Weave 25yds mm $150/yd 316 oz 50w Satin Weave 25yds mm $400/yd Minimum order 1 yd VISA-MASTERCARD FAST SERVICEI ORDER TOLL-FREE 800-338-1278 Dealer & Mig inquiries welcome Send $3 postage & handling FREE catalog I.. Model IdIng IS \ MOSTLY MOUNTING presents entirely new approach installations works well wIth popular kits Including ARFs easy accurate sure fire MOSTLY MOUNTING system gives better model builders stress controls include complete treatments tanks engine mounts canopies cowls wheel pants retracts other subjects Youll find MOSTLY MOUNTING refreshing interesting way great flying trouble free models BOKO14$1495 Please Try Dealer First Direct Sales Please Add $300 HARRY 3 HICLEY INC P o Box 532 GLENWOOD IL 60425 No-Cal - Rubber Kits t Balsa Stk N Tssue ConstructionConst uct No priorRequ es building---cut ng experience requiredf tt ng Bu ds w th p e Assembles easily withp n ed Bass parts pre-printed & die-cut5 pwood & Japanese partstasue Build quickly & fly great Select Micro-Cut Oualily wood parts Ouslity hardware included Legal FACNo-Cal events 16 wingspan Available local hobby shop drill slot clearance rudder/fin rear stab rod spacer insert main bearing add stab drill jig over bearing Drill through rear jig hole top slot will Continue drill series line holes rotating jig front bearing bottom slot Now drill opposite side Remove jig insert ewelers needle file file webs between holes Presto neat slot Add pushrod antenna housing use steel cable pushrods Hobby Lobby sells cable ousing 20-foot lengths Cut cable housing length slightly oversized set aside Using hand drill make right side rudder pushrod exit Drill bits designed cut sides can rather soft material Once bit through fuselage lay drill over elongate hole pushrod will exit angle Remove drill complete angle ile Continue file until pushrod housing angle will allow cable run directly rudder horn bending Add housing epoxy around exit Install cable clamp edge canopy opening position line up servo arm Lay fuselage tight side Looking inside housing cable should lay against inside fuselage long gentle curve line up servo ann Use long piece music wire carefully add globs epoxy five six inches complete leave fuselage its side dry Remove cable trim excess epoxy housing rudder exit solder link elevator pushrod connect cable stab horn temporarily install cable housing horn fuselage Again clamp cable inside canopy opening sure housing close horn close keep horn freely moving through full up down hold housing position usually wedge small piece balsa over top housing smallest point fuselage Now lay fuselage its left side add epoxy dry add teflon antenna housing down rudder LE fuselage cannot glue teflon anywhere stick short pin through end tubing inside rudder/fin keep sliding forward pushrod antenna tubes can also held place fabricating few soft balsa foam bulkheads lightly gluing fuselage boom add plywood keel inside fuselage add strength give base add blind nuts towhook also makes good base add block hardwood screw angle-type hook Its shown plan also add piece l inside LE area other anti-crush bar hard landings Finish Sealy recommends spray 38 Model Aviation PTOR THROW AWAY YOUR COLLETS CHUCK & WRENCH USE oun ADAPTOR & KEYLESS CHUCK 5132 CAPI ON ALL EEPOWER TOOLS INCLUDING m [IMITa EXIBLE SHAFT RUNS 100% TRUE & CONCENTRIC ATFULLRRM NO 501 ADAPTOR ESS CHUCK $1895 tASO 395 00 NOT NEED ADAPTOR TO USE KEYLESS CHUCK STEEL SAW AND ARBOR __________ HARDENED GROUND & POLISHED STEEL USED FOR CUllING PLASTIC WOOD SOFT MErALS LEXAN PLEIGIAsS & ErC AVAILABLE IN 0060080100125tH 01656 5055053 525 028 032 ThICKNESS NO 502ARBOR$000 IOUR1 OUTSIDE DL54ETER IS 5675 EA NO 503VXOI4X1I4SAW$ooo ONLY WORK wrr OUR ARBORI ABRASIVE CUT-OFF BLADES FIBERGLASS REINFORCED-RESISTS BREAKAGE-CUT STEEL BRASS COPPER ALUMINUM AND OTHER METALS ALL BLADES 1/32 THICK WITH 1/4 HOLE SIZE NO PRICE SIZE NO PRICE 1112 AB2100 3ABS150 2 A83 100 ARBOR 503 600 SAWS AND CU2OFF BLADES ONLY WORK WITH OUR ARBOR MICRO NONEED FOR FLINT OR MATCHES SELFBUTTON FOR MICRO SIZE ADJuSTABLE FLAAIE TRAT BURNS AT 237S FOR UP TC STARTING3 HOURS OPERATES ON STANDARD PRESS THE PIEZO SELF-STARTING CIGARETTE LIGHTER BUTANE AND IS TORCH-REFILLABLE TANK FITS COMFORTABLY IN ThE PALM OF YOUR HAND AND IS MT770-MADE OF HIGH IMPACT RUBBER WHICH Blow TorchALLOWS FOR SAFE NON-SLIP GRIP HIIh e ol boIa, S35OO SUPPLIED WITH CAN OF BUTANE BBIBBBSOZS6WEFDRCATW WHEN DROORROS AD] 03 00 EASTERN TOOL&SUPPLYCOCDOADOSL5B DRBERS 2129551006 149 GRAND ST NYC. NY 10013OFFCS 21222E3149 CATALOG FREE WITH ORDERFP& 2129251DIO Saga Works iron-On Coverings No Need Use Any Prep Easy Use Real Breakthrough Covering Application Before beginning construction THE WOODPE KER aerate ply & balsawood parts sands Micro-holes will allow glue penetrate wood creating super strong structure After completing aircraft THE WOODPECKER aerate ply & balsawood surfaces thousands Micro-holes will allow trapped gasses crested heating covering material escape No outgassing means no bubbles sags covering stays put looks great long after first applied apply film over film ply convert THE WOODPECKER what ever configuration desire 123 4 wheels ate primary covering iron smooth apply next film Its easy NOTE Surface must tree sanding dust prior covering Warning This toy out reach children See Hobby Dealer First Check/MoneyOrder Directly UNIQUE MODEL PRODUCTS P0 Box 2229 Lake Arrowhead CA 92352 iw$ 0336-5602 Visa & M/C AcceptedSorry No CODsDealer Inquiries Invited. automotive primer first primarily finding pinholes could add epoxy gel-coat eliminate pinholes would add weight very litfie strength first Heat Seeker sprayed white automotive primer filled pinholes Model Magic sanded primed again finished white automotive lacquer finish chips easily primed second fuselage same way finished white Formula U much harder finish heavier lacquer third model sanded got out old Miller spray unit sprayed white Hobbypoxy undercoat quick spray hardener filled pinholes thinned out Stuff wiping off excess After light sanding fuselage sprayed white Hobbypoxy paint again using quick spray hardener super-hard light finish Whatever spray white Other colors will absorb heat weaken fiberglass highly recommend covering wings stabs rudder MonoKote Vinylwrite lettering hinge wing flaps ailerons MonoKote tabs use tape tape flaps bottom ailerons top wing Radio Jam presently using Futaba 7UAFS S-148s fuselage standard servo comes JR X347 sailplane version fits better flaps have two S-9601s model S-3002s other Both use same case have metal gears 3002 slower has higher torque Both same size Airtronics 401 ailerons use two S-5102s really S-133 metal gears third plane uses JR 341s wings plan show servos held place short blocks glued door blocks should marked put vise drilled tapped servo screw glued doors Putting screw block vise will keep block splitting like use servo tape leave blocks off smear some epoxy plywood side door cover Saran Wrap lay face down slick surface add weight allow dry dry peel off wrap have super-slick surface tapeit Continued page 43 $4400..ig span aing span 3-4 ch radio Design s like rails ages ot instructions auded AMA Grand Openingl Build & Fly GE Orders Call 1-800-645-KITS Fer infermalien caii 609-448-1122 GENERIX East Whdsor NJ 09520 Tomorrows Kits Affordable Prices1 Write Free Catalog $500 COD Custom Kit Cutters s Anyone Elses 40 Model Aviation WOODPECKERTM Pat Pend First Convertible Multi-Purpose Covering Tool NOW YOU CAN COVER LIKE THE PROS No Bubbles Covering Looks Great Long After Its Applied Film Over Film No Problem Steel Construction Made USA Heat SeekerlKincaid Continued paqe 40 must slick Ive tried several servo tapes best Ive used Permabond Radio Shack Balancing everything finished assembled sit plane floor balance aft position plan use Tape small paper cup top nose Pour lead shot until plane balances Remove nose cone battery sit hang fuselage vertical pour lead shot nose Mix about tablespoon epoxy pour top shot epoxy has cured add round disk foam reinstall battery three Heat Seekers weighed 72 ounces Flying Heat Seeker flies much like fast Scooter way flies will depend mainly pilot airplane Most experts know want set up surface throws based fast plan fly whether plan use dual rates etc throws plans will get average novice safely air Final correlation between rudder/aileron flaps/elevator will depend radio trimming technique Most fliers pretty good adjusting new model first flight go through hand launching stab adjusting take chance breaking new plane sure-fire safe first-flight procedure Balance CG mark shown drawing Put towhook directly under CG Place fuselage table workbench can remove wings Shim fuselage until top tailboom level table position wing will approximately 14 150 positive incidence radio adjust stabs 00 setting should measure same distance table center stab leading edge stab trailing edge felt-tip pen put small mark rudder/fin stab leading edge CG wing angle stab setting towhook position first launch should perfect glide should nice level will find can grab fuselage under wing forced awkwardly launch holding tailboom Good luck have fun ces Fiberglass fuselage foam cores Bob Sealy 2530 Zeb Warren Road Cookeville TN 38501 Tel 615 526-4770 Thin carbon fiber kevlar thread Bradley Model Products 1337 Pine Sap Ct Orlando FL 32825 Tel 407 277-9132 Eight-inch-wide balsa sheeting Superior Aircraft Materials 12020-G Centralia Hawaiian Gardens CA 90716 Tel 800 488-9525 best A2 wing rods Dave Squires 935B La Mesa Terrace Sunnyvale CA 94086 Tel 408245-8111 994 43